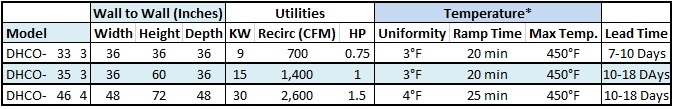

Cabinet Ovens manufactured by DELTA H offer a high quality, reliable, and precise industrial batch oven at an extremely competitive price. Designed for versatility and growth, our ovens can be upgraded with advanced packages that meet AMS 2750E, CQI-9 and operate as a class 1 system.

The DELTA H Cabinet Oven(DHCO) is a “plug and play” package allowing you to begin returning your investment almost immediately. Designed as an easy to operate heat treatment oven or curing oven. Typical applications include drying, composite curing, powder coating and paint curing, heat treating, aging, annealing, heat-setting, stress-relieving, R&D, and other industrial process heating needs.

All of our industrial cabinet ovens feature an adjustable side wall mounted internal ductwork system for precision directional air flow. The blower and heating unit are top-mounted for easy accessibility and maintenance. All industrial cabinet oven models are designed with an integral top plenum for hot supply air. Heated air is distributed uniformly into the work chamber from the side walls via our exclusive adjustable directional duct design. The dual airflow pattern design pulls air through the ceiling mounted return which results in an overall temperature uniformity of+/-3° F. The balanced airflow and uniform temperature results in consistently successful heat treatment batch operations.

The DELTA H industrial cabinet oven is constructed of insulated panel sections. The “U” shaped wall and ceiling panels fit together so that all of the heat is isolated on the inside of the oven. Panel sections are lined 4″, 6″ or 8″ inch thick insulation. Upon completing the installation of the insulation, cover panels are placed on the exterior walls to complete the assembly. The final cabinet oven structure is a double walled and structurally sound heat treatment enclosure that is thermally efficient up to 850°F maximum.

Our cabinet ovens come standard with a single or double door depending on the overall width of the system. Door units are the same thickness as the wall panels and are designed to allow for maximum thermal expansion on the inside panel. The rigid, yet expandable design reduces door warping and released latches which can lead to a ruined batch. Explosion relief latches or positive locking systems are used depending on the oven type and classification.

Control enclosures ship standard with an easy to operate set-point temperature controller. Optional advanced electronics/ controller packages and recorder systems are available. Please contact us with your requirements.