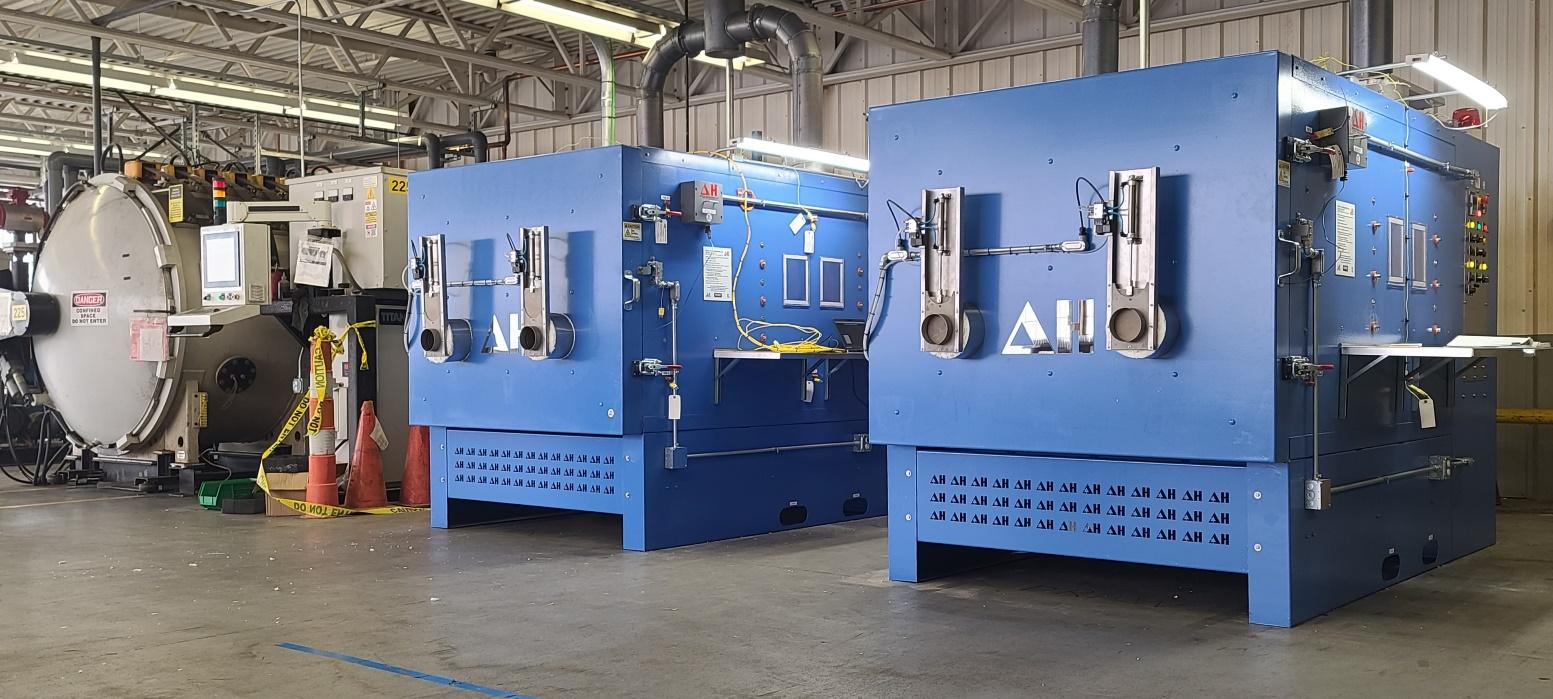

Elyria Ohio: DELTA H® recently delivered twin furnace systems to RIDGID® TOOLS. The challenging requirement was to heat parts from ambient to 975°F, soak for 2 hours, cool to 120°F as fast as possible, soak 2 hours, then repeat. The solution was an innovative design featuring all stainless steel interior and low mass ceramic fiber insulation for minimal heat retention. High powered electric heating elements, coupled with pneumatically operated blast gates and proprietary ductwork / venting enabled the system to accomplish the requirements with precise repeatability total reliability as a “cold to cold” heat treating operation.

The furnaces feature a work volume of 3 feet wide, 3 feet high and 4 feet deep with a maximum continuous operating temperature of 1,200°F. Both are designed to receive baskets of parts from a nearby Ipsen Titan vacuum furnace and include a floor guide system to enable precise load placement. Temperature control and data acquisition are provided by Eurotherm Nanodac Controller / Programmer / Recorder and iTools Engineering software. Though not requiring aerospace pyrometry requirements, the system qualified as Class 2 (+/- 10°F) and features Instrumentation Type C with a load thermocouple jack.

“We had a challenge with utilization of our vacuum furnace where a secondary heat treatment might be better accomplished with a convection furnace. This would dramatically increase the production capacity of our vacuum furnace and fully optimizing this process. The extreme and demanding rapid heating and cooling cycles called for a unique convection furnace design. DELTA H® answered the call with a version of their high performance furnaces featuring extreme powered heaters and radical ventilation – including door mounted vents to bring cool air directly across the furnace load. The result has been perfect performance and we could not be more pleased.”

Nicolas (Nic) Willis – Emerson Professional Tools, Metallurgist / Heat Treat Manager

“I have known Nic for many years, including the Cleveland Chapter of ASM International where we both served as officers – and was honored to nominate him to the Heat Treat Today 40 Under 40 Class of 2020. When I became Director of Sales for DELTA H® I was pleased to let him know we build furnaces for demanding heat treating applications. The process here was a challenge, but our CTO Richard Conway answered the call with an innovative and unique furnace design. The performance and results speak for themselves and it is an honor to be of service to the legendary RIDGID® TOOLS.”

Rosanne Brunello – DELTA H® – Director of Sales

Nic Willis – Emerson Professional Tools / RIDGID®, Chief Metallurgist, Heat Treat Manager

Richard Conway – DELTA H®, Director, Chief Technology Officer

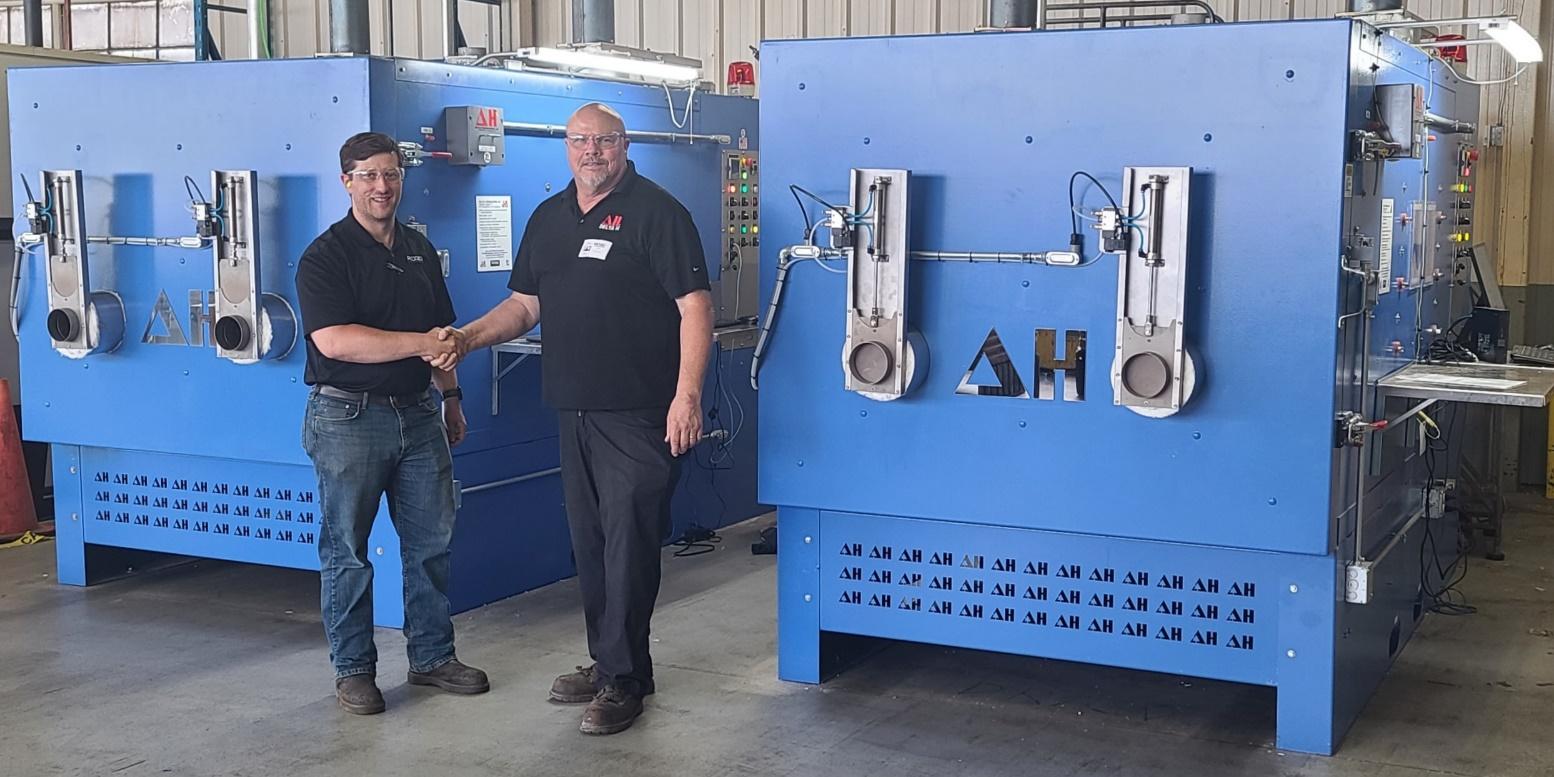

Rosanne Burnello, DELTA H® Director Of Sales, has the honor first revealing our logo

A DELTA H® tradition – only performed upon the full acceptance and commissioning

of a system – and proven worthy

DELTA H® Twin SCAHT® Furnace Systems Optimize Utilization of Ipsen Titan

Vacuum Furnace at RIDGID® TOOLS