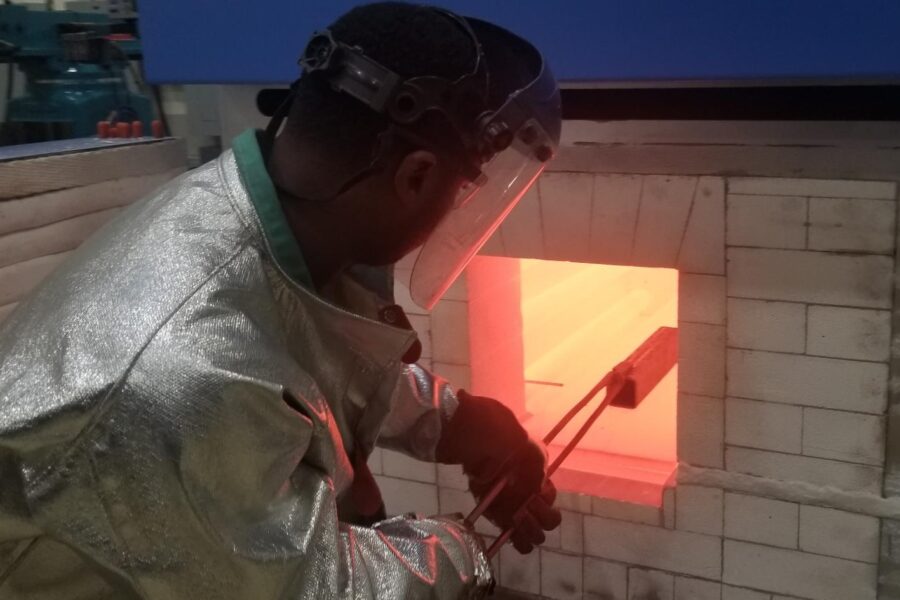

Joint Base San Antonio – Randolph, TX: DELTA H® recently commissioned a dual chamber model DCAHT®-181248-1200/500-MIL, a DCAHT®-241672-1200/500-MIL, and a large single chamber SCAHT®-303048-1200-MIL. The project is for supporting T-38 Talon Repair Inspection and Maintenance, or TRIM, modifications for performing localized, depot level maintenance to replace or repair key parts in order to keep these valuable training platforms mission ready. USAF depot level heat treating requires full compliance to AMS2750G. The heat treating systems provided by DELTA H were for replacing existing systems which proved too troublesome or costly to try to qualify and were never designed for modern pyrometry…

Media CaptainDecember 12, 2023