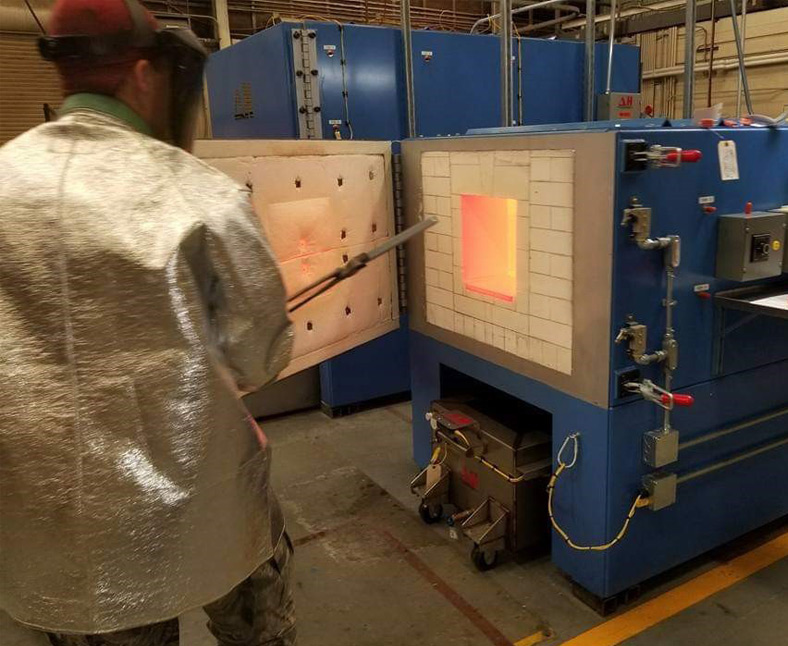

Aerospace Heat Treatment & Industrial Furnaces

Aerospace Heat Treating Equipment

DELTA H manufactures heat treating equipment for the aerospace industry that meets and exceeds the strict and demanding requirements called for by AMS2750H and Nadcap accreditation when processing aluminum alloy, tool steel, titanium, PH stainless steel, and composites. Our heat treating furnaces & ovens guarantee times, temperatures, uniformity and are supported by unparalleled repeatability.

Purchasing one of our ovens allows your organization to bring the process in-house, which means no outsourced heat treating cost—and typically, most of our clients boast of an ROI of fewer than two years and doing so without impacting CAPEX funds. Your system will literally pay for itself.

At DELTA H, we pride our self on being the only furnace & oven manufacturer with a dedicated division, knowledge, and products to specifically meet the needs and demands of aerospace OEMs, MROs, Component Repair and Overhaul Facilities, and Aircraft Parts Manufacturers. We serve large corporations such as Lockheed Martin, Boeing, FedEx, Aviation Technical Services, Curtis Wright Controls, Honda Jet, branches of the United States Armed Forces as well as medium to small maintenance hangars and parts manufacturers. All rely upon DELTA H to solve their heat treat challenges and provide quality, value, and timeliness to keep their aircraft flying quickly. We have developed an impressive brand and reputation over the years and have “earned our wings” in aerospace heat treating.

Heat Treatment Ovens & Industrial Furnaces

DELTA H offers numerous types of industrial furnaces & heat treatment ovens for materials applications requiring walk-in ovens, bench top furnaces, cabinet style ovens, composite curing ovens, powder coating ovens and associated equipment all of which can be configured as a batch oven or a continuous system. A variety of models are available in-stock that are gas-fired or electric heated or we can custom design a system tailored to your specific size and heat treatment application.

Popular systems include our Walk-In Oven Series which is available as a “Turn Key” system with installation and training included or as an easy-to-install kit system. Multiple options are available for installation, warranty, and start-up on all models including remote and full on-site guided assembly. The DELTA H Walk-In Oven is ideal for a wide variety of industrial thermal processing/ heat treatment oven processes such as composite curing, powder coating, baking and drying as well as just about any other industrial application including new or emerging technologies. Do not hesitate to contact us with your specific application as we offer custom engineered and designed systems.

All of our ovens feature our exclusive and proprietary directional duct system which allows for total adjustment of airflow in order to optimize temperature uniformity. Our industrial furnaces & heat treatment ovens are relied upon by leading companies where strict compliance to standards as well as high performance and total reliability is required for continuous 24/7 operation.

Consulting Services

a

Considering a new industrial furnace or heat treatment oven and don’t know where to start? Perhaps you have a system already in place and simply need maintenance or you are in the market for an entirely new system. Our in-house combustion engineer, Richard Conway, who possesses 40+ years of experience in the industrial furnace, heat treatment oven, kiln, and thermal processing industry can help. Richard will perform a time-tested methodical engineering analysis to determine the root cause of any current bottlenecks in your process and work with you to modify or replace your current process resulting in increased performance, operation and reducing your expenses.

When it is time to upgrade to a new furnace or heat treatment oven, our engineering and design team with years of design and manufacturing experience will bring your vision to life.

If your company already has an idea of your heat treating needs, we can guide you through the quoting and purchasing process for your new industrial furnace or heat treatment oven. Whether you are interested in a new application requiring heat processing, a full ROI study analysis or a quote for a new oven or furnace – we are here to help!

Our Reviews

Our Clients

Industries Served

- Heat Treatment and Industrial Metal Processing

- Heat Treating Aerospace Metals

- Heat Treatment Oven Applications

- Composite Curing Ovens

- Used Equipment / Brokering Services

Thermal Processing Including ferrous alloys (steel), copper, aluminum, stainless steel, brass, bronze, cast iron, and other metals.

Heat Treating Furnaces Including annealing, hardening, tempering, aging, integral quench, normalizing, solution heat treating, stress relieving, and other metallurgical processes

Heat Treatment Ovens & Furnaces Including batch ovens, dual chamber furnaces, tool room heat treatment furnaces, box ovens, heat treatment oven, car bottom, atmosphere heat treating, heat treating for aluminum, drop bottom ovens, aluminum aging ovens – AMS2750H compliant, gas fired or electrically heated systems and continuous systems.

DELTA H is well known in the aviation industry for our exclusive dual-chamber ovens designed for aerospace heat treatment (DCAHT) technology. Our systems are ideal for aerospace back shops or industrial aluminum heat treating job shops, tool rooms, and research and development “Blue Streak” rapid prototyping, and Aircraft On Ground (AOG) applications where extreme flexibility is required.

We provide industrial furnaces with an inert atmosphere designed for machine shops where full compliance is required to aerospace pyrometry standards. These systems are used for all aircraft grades of aluminum (2024, 6061 & 7075), PH stainless steel, tool steels, and titanium. Systems come complete as turnkey installations with full training and service support.

Low-temperature heat treatment ovens are used for infinite applications including composite curing, paint curing, drying and powder coating. We provide standard ovens as well as custom specialized ovens for simple to highly complex processes including walk-in ovens, bench top ovens, cabinet ovens, truck or cart ovens – both gas and electric heat – batch ovens or continuous systems available.

Industrial Finishing Including: powder coating and wet paint curing, electroplating ovens, drying / dry off and cure ovens, gas and electric applications. We provide fast delivery kit ovens with full service support as well as our DELTA H Economy Line (DHEL) models of cabinet, truck, and walk-in ovens.

Our Used Furnaces Division is long established and well-known for listing/ selling/ brokering used and surplus industrial heat treatment ovens and processing equipment. Turn your surplus equipment and “dead money” into cash.