Burloak Technologies Commissions Two (2) DELTA H® Heat Treat Furnace Systems for Additive Manufacturing (AM) and Aerospace Applications

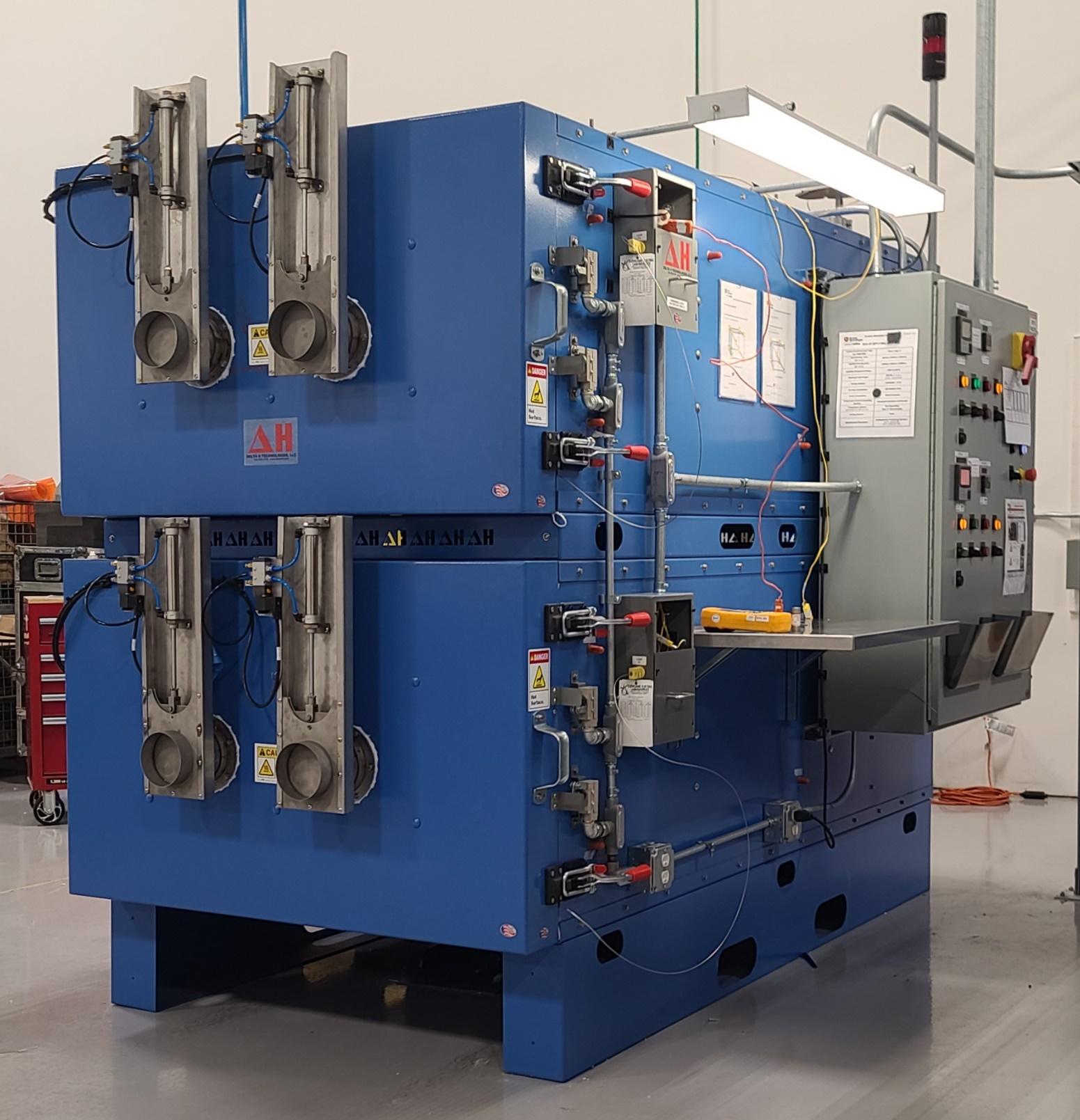

OAKVILLE, ONTARIO / BURLOAK TECHNOLOGIES: Burloak Technologies recently received and commissioned two (2) DELTA H® furnace systems for use in both R&D as well as full-scale additive manufacturing production of aluminum products. Burloak reported that parts initially being processed in the two furnace systems included items for the Canadian Space Agency and revolutionary communications satellites.

The two furnace systems include a single-chamber (SCAHT®), fully-automated, horizontal quench, solution heat treating furnace capable of operating from ambient to 1200°F followed by rapid quenching in less than seven (7) seconds – a requirement for processing critical-application aluminum parts. This SCAHT® furnace is also capable of slow quenching geometrically complex AM parts. The systems provide precise duplication of heat treat cycles. Included is a comprehensive data acquisition system in full compliance with AMS2750G – Instrumentation Types A, B, or C and can produce irrefutable, scientifically defensible batch records. As safety is paramount, the fully enclosed quench system met all the strict Canadian safety standards as well as all electrical and design safety requirements of CSA/UL/CUL and NFPA.

Burloak also commissioned a dual chamber (DCAHT®) aluminum aging oven system. Both chambers are identical and can operate from ambient to 600°F with precision control and uniformity. A unique feature is “Rapid Cooling” whereby overall cycle time for parts is minimized.

All chambers are 24 inches wide, 18 inches high, and 48 inches deep. All qualified as Class 2 and proved capable of Class 1 uniformity. In both the SCAHT® and the DCAHT® operators never have to handle dangerous hot parts. With the quenching system on the SCAHT® as well as Rapid Cooling on the DCAHT, all heat-treating cycles are fully automated from “cold to cold” with operators only attending to load or unload part trays.

“DELTA H builds straightforward, easy to use heat treatment ovens that are exceeding our internal and customer quality requirements. Training personnel from operations, maintenance and quality is an easy and painless process. The transparency of the systems will be pleasing to customer, AS9100 and Nadcap auditors”.

Peter Adams, Burloak Technologies Chief Innovation Officer and Co-Founder

“The systems provided to Burloak represent a new chapter in our dedication to the aviation and aerospace industries as well as additive manufacturing in general. It is very humbling to be among the technology providers to such an innovative and pioneering company as BURLOAK TECHNOLOGIES.

Ellen Conway Merrill, DELTA H Vice President

About BURLOAK TECHNOLOGIES:

Burloak Technologies, a Division of Samuel is Canada’s leading supplier of highly engineered additive manufactured components for demanding applications.

About DELTA H TECHNOLOGIES:

DELTA H manufactures heat treating equipment designed for serving the uncompromising standards of the aerospace, defense, medical, and automotive industries with guaranteed compliance to the strict and demanding requirements of AMS2750G, Nadcap accreditation, MedAccred, and CQI-9 standards.

Chief Innovation Officer and Co-Founder

Burloak Technologies

Vice President

DELTA H TECHNOLOGIES, LLC

Fully Automated AM and Aerospace Aluminum Heat Treating