FOR IMMEDIATE RELEASE:

President Biden Visits Royal Air Force Mildenhall During Commissioning of New Aerospace Heat Treat Furnace

Bury Saint Edmunds, England | Royal Air Force Base Mildenhall

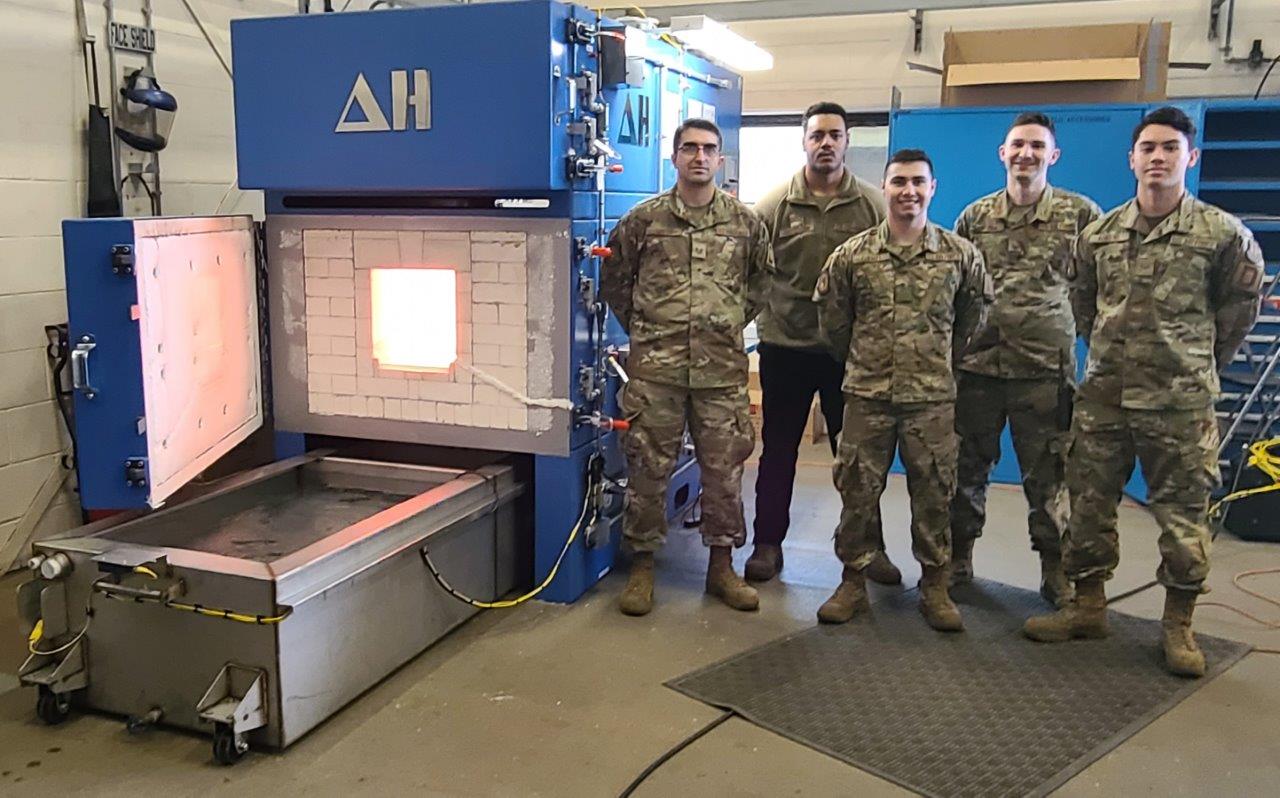

United States Air Force personnel stationed at RAF Mildenhall in the United Kingdom recently commissioned and received full training on the use and maintenance of a DELTA H® TECHNOLOGIES universal dual chamber aerospace heat treating (DCAHT®) furnace. The furnace which will help maintain KC-135, CV-22, C-130 aircraft, and F-15 fighter jets assigned to RAF Mildenhall or nearby RAF Lakenheath air stations, was designed by DELTA H® to rapidly heat treat all common aviation grade metals and alloys necessary for aircraft maintenance. The furnace is fully compliant with USAF/NAVAIR Tech Order 1-1A-9 and SAE-AMS2750G. The training received by the Airmen at RAF Mildenhall included essential instructions in heat treating, as well as furnace calibration practices like temperature uniformity surveys (TUS) and system accuracy tests (SAT) and culminated with each Airman receiving Certificates of Training.

The highly specialized furnace features an upper chamber convection system, 18” wide x 12” high x 48” deep, capable of Class 1 (+/-5°F) from 200°F to 1200°F and a lower chamber radiant heat system, 12” wide x 12” high x 36” deep, capable of Class 3 (+/-15°F) from 1000°F to 2000°F with air or argon atmosphere. A roll-away quench tank features dual baths for water and oil quenchant. The controls and data acquisition provide detailed batch records of heat treated parts, including quench delay, as well as automatic tracking of thermocouple usage and calibration intervals. Numerous US and Allied Armed Forces facilities around the world rely on these systems by DELTA H® for aircraft maintenance heat treating.

The training was interrupted by an unexpected visitor to RAF Mildenhall. The hangar next to the Metals Tech Shop, where the furnace was being commissioned and the training was being conducted, was the epicenter for the arrival of a top-secret VIP. When the Air Force Band began practicing “Hail to the Chief,” it became obvious that US President Joe Biden would be making an unexpected visit to the base. While the President’s visit was not related to the furnace commissioning, it was a singular privilege for DELTA H® founder and Chief Technology Officer, Mr. Richard Conway and wife Mary, to experience this presidential visit and get a few candid photographs of Air Force One.

The commission and training took place during a time when COVID-19 restrictions were at their peak in the United Kingdom. Mr. and Mrs. Conway received a “essential defense activities” quarantine waiver, signed by the base commander, and were restricted to one taxi ride each way between RAF Mildenhall and Heathrow as well as COVID-19 testing prior to their return to the US. Any additional on-base or off-base travel could have resulted in a heavy fine and a 10-day forced quarantine.

About DELTA H Technologies

DELTA H manufactures heat treating equipment designed primarily for serving the uncompromising standards of the aerospace & defense industry with guaranteed compliance to the strict and demanding requirements of AMS2750G and Nadcap accreditation. DELTA H is proud to serve leading aircraft OEMs, aircraft MRO facilities worldwide, aircraft parts suppliers and the Armed Forces.

For More Information

Ellen Conway, Vice President of Sales, econway@delta-h.com, 740-756-7676